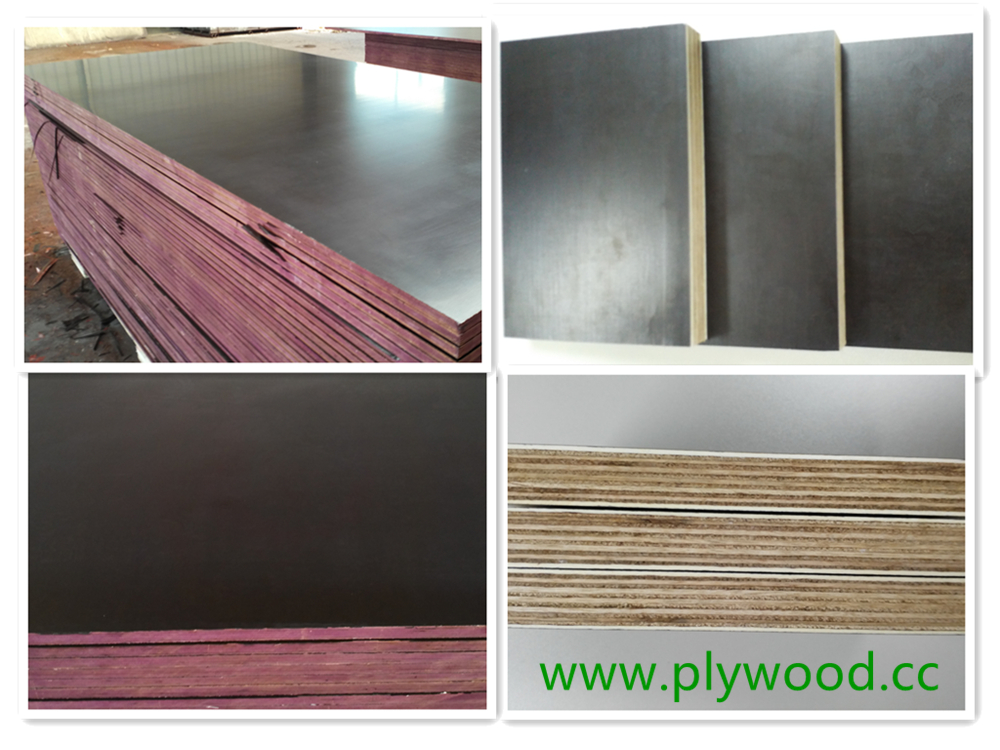

Top-Quality black film faced plywood :

For high-end applications

If you have strict requirement in the quality

Specifications: black film faced plywood

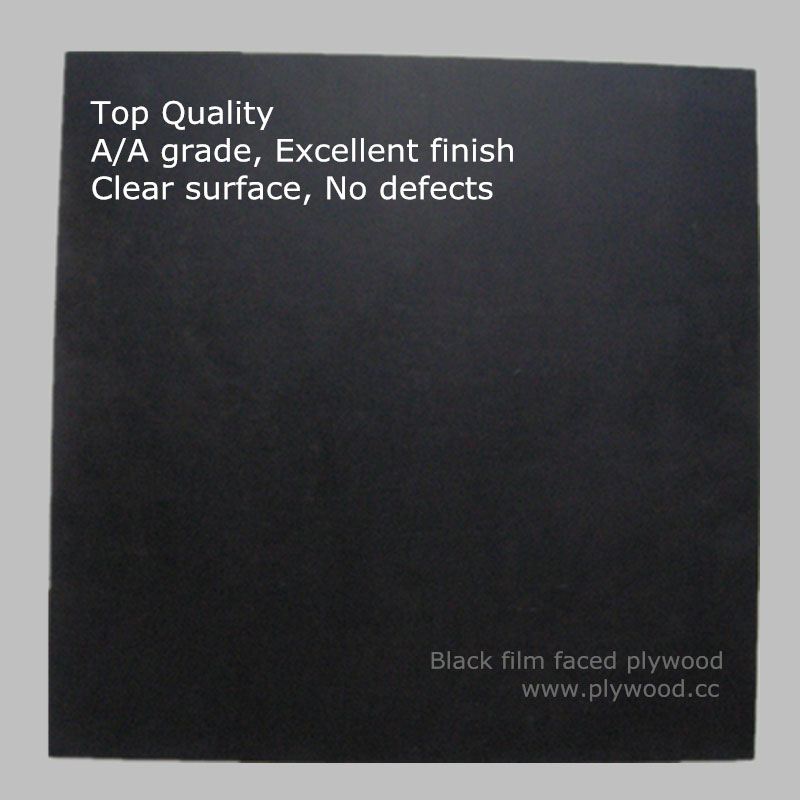

- Grade:Top Quality, A/A grade

- Film color:Black film(Dynea film,brown film,red film, green film are also available)

- Appearance type: slip type / wiremesh(anti-slip) type

- Core: poplar, hardwood, birch or combi

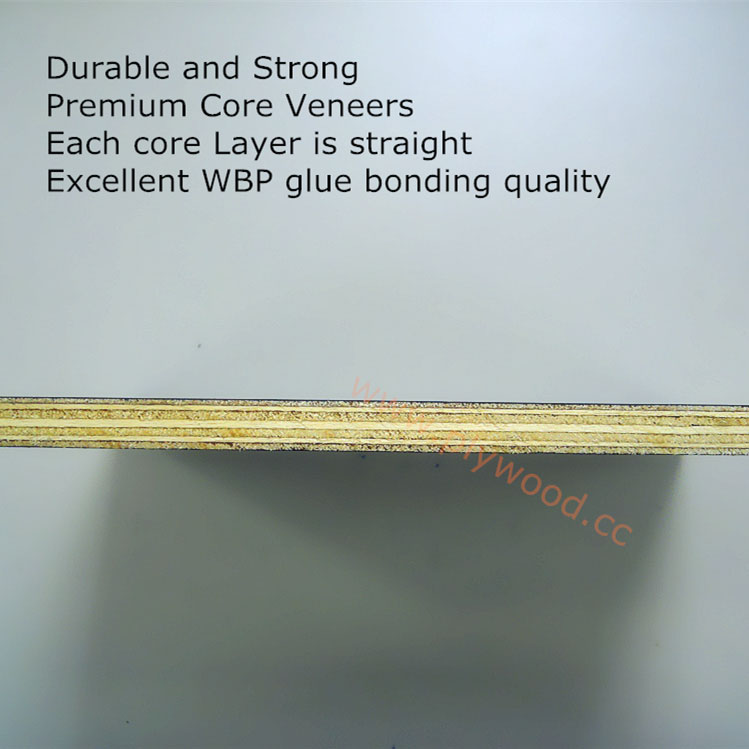

- Glue: WBP(phenolic), Premium WBP melamine

- Size: 1220X2440 (4’x8′) / 1250×2500 / 1200x1800mm / 1200*2400mm or upon request

- Thickness: 4, 6, 9, 12, 15, 16, 18, 20, 21mm, any thickness within 4mm-50mm

Why the quality is high ?

High grade veneers

Premium WBP glue

Higher pressure under heat !

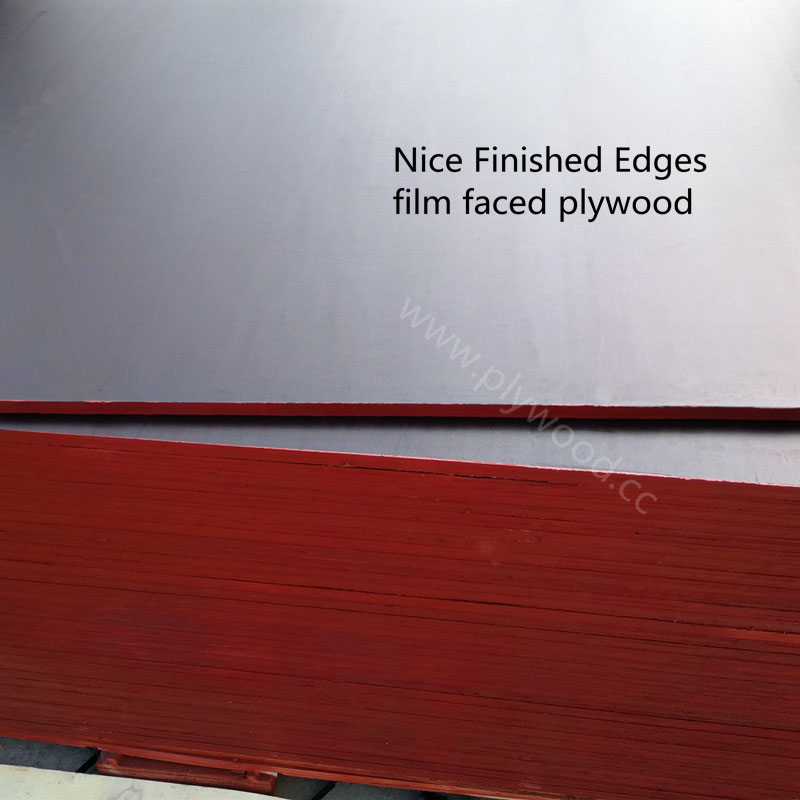

Edge:Edges sealed with water proof painting, painting color as per your request

Contact us to get the best quote now !

2. The characteristics of poplar film faced plywood

(1). The appearance of A/A grade looks good. The appearance of B/B grade still looks satisfying . The appearance of economical grade is acceptable .

(2). The poplar film faced plywood is very flat and smooth .

(3). The grade of core varies from high grade (A+ or A grade) to low grade (C+ grade) . The quality of C grade core film faced plywood can not be guaranteed , so we don’t supply C grade core film faced plywood.

(4). The poplar core veneers can be whole piece core veneers(A+ grade, A grade) , medium size core veneers (B+ grade, B grade) and small size core veneers (C+ grade) .

(5). The inner quality of poplar film faced plywood varies from best quality to economical quality .

(6). A/A grade Poplar film faced plywood is cheaper than A/A grade birch/hardwood film faced plywood. So we can say that poplar film faced plywood is good quality and economical .

3. The common construction/quality-requirement

Customers usually require the poplar film faced plywood as the following:

SEQ No. PFFP-1:

Film faced plywood,A/A grade, imported brown film , A+ or A grade poplar core, WBP(phenolic / melamine) glue

SEQ No. PFFP-2:

Film faced plywood,A/A or B/B grade, China local black (or brown) film , A+ or A grade poplar core, MR glue or WBP(phenolic / melamine) glue

SEQ No. PFFP-3:

Film faced plywood,economical grade, China local black film, B+ or B or C+ grade poplar core, MR glue

4.The application of poplar film faced plywood

Use as concrete shuttering form, building materials, for making high quality furniture and so on .

5. The staple market of poplar film faced plywood

About 60% of poplar film faced plywood are exported to Europe , about 40% are exported to Middle East and other countries .

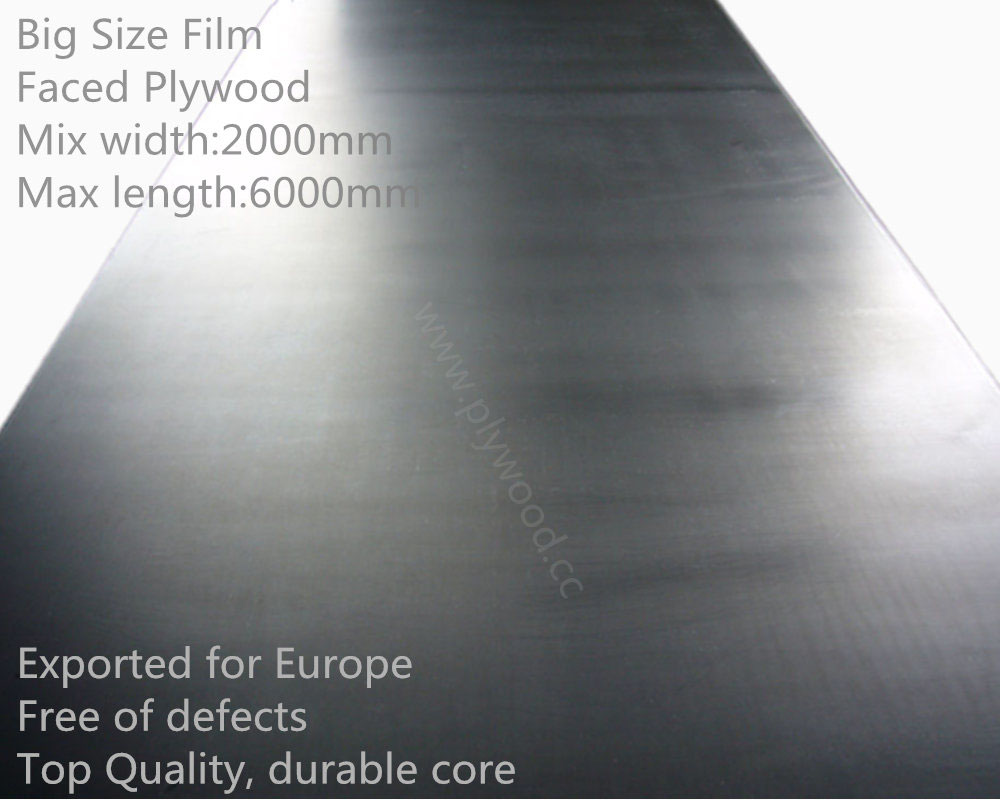

The quality of black film paper in China varies from economical quality to the top quality .

Black film of top quality has much better water resistant properties . So when you buy black film faced plywood, you had better confirm the quality of the black film paper with your suppliers .

But please also keep in mind that black film paper of top quality is much more expensive than black film paper of economical quality .

Customers import not only brown film faced plywood of top quality , but also black film faced plywood of top quality or even black wiremesh plywood .

Related Products:

Loading Quantity:

20'GP(contains 8pallets,22CBM)

40'HQ(contains 18pallets,50CBM)

Standard Seaworthy Packing method:

plywood is wrapped with a plastic bag and packed with packing plywood/MDF/carton (upon your request) ,loaded on Pallet .

Delivery Time: Within 15-25 days after got the deposit / sight L/C

Port of Loading: Qingdao port or Lianyungang port, China

Minimum Order Quantity: 1x20'GP container 8pallets/22cbm

Payment Terms:

1. 30%T/T as deposit, 70% T/T against B/L copy

2. 100% Irrevocable L/C at sight