Poplar Film faced plywood

Poplar Film faced plywood is the film faced plywood with poplar core veneers. Poplar used for shuttering purpose, i.e. poplar forwork plywood.

About China Poplar Film faced plywood

A large number of poplar trees are planted in China. A lot of poplar trees are planted on both sides of the road. China has a huge volume of poplar trees . So most of China film faced plywood are made of poplar.

Advantages of Poplar Film faced plywood

Poplar film faced plywood is durable

Poplar film faced plywood is very durable. High quality poplar film faced plywood can be repeatedly used for more than 10 times, or even more than 20 times. Medium grade poplar film faced ply can be used for 5-8 times. Some simple projects do not need high grade shuttering plywood, it will be a wise choice to choose economical-grade poplar film faced plywood, which can be used for 2-4 times.

Poplar film faced plywood is cheap

Poplar grows much faster than other commercial timber. Therefore, poplar is a tree species that can be supplied in large quantities. Because of this, poplar plywood is relatively cheaper than other materials.

It is cheap and good. Who would not prefer poplar plywood ?

Specification of poplar film faced plywood

Specification of poplar film faced plywood

1.Product name:

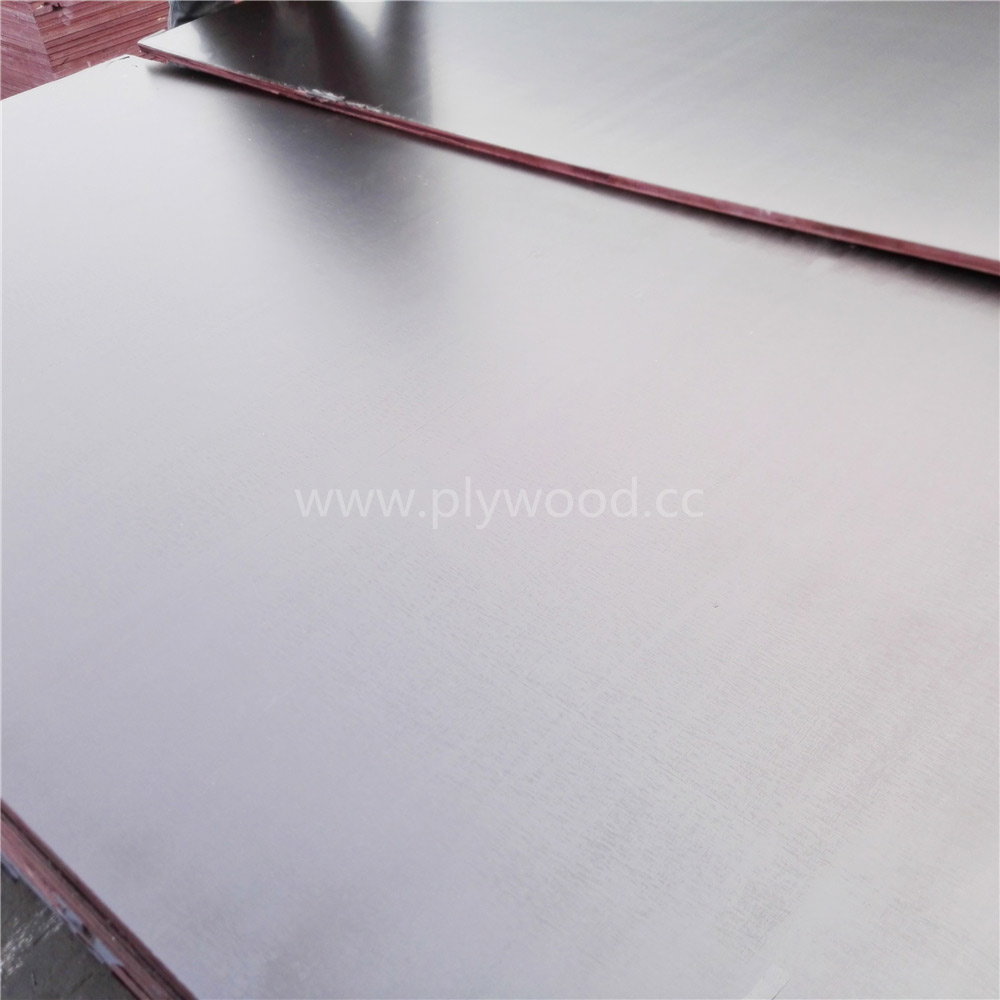

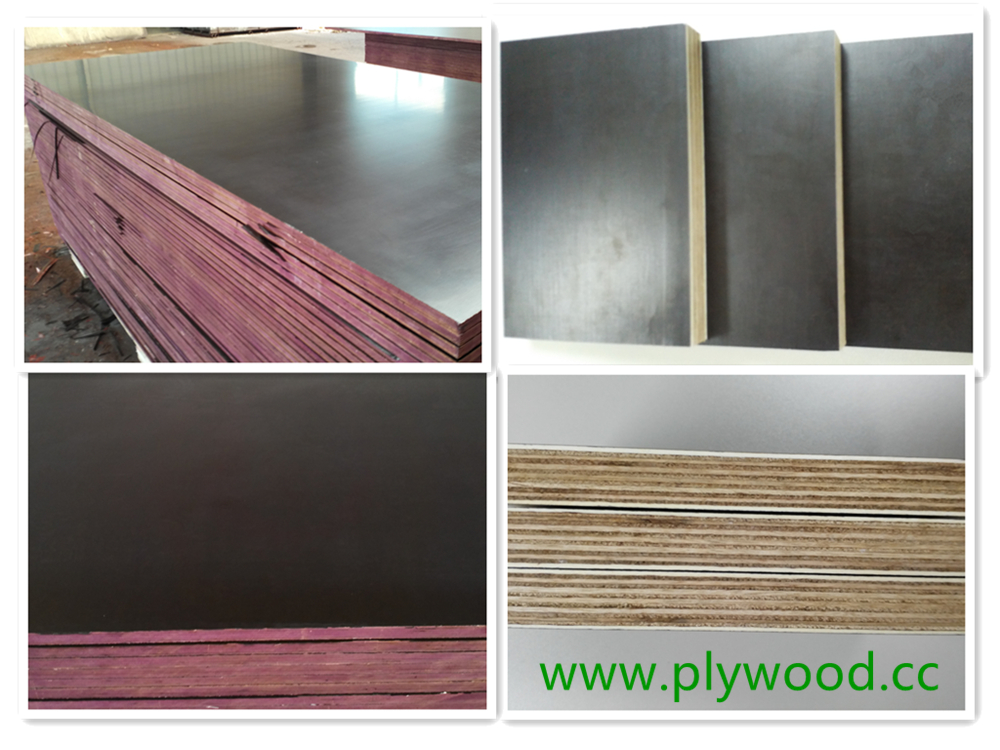

(1). Color of film: black color / brown color

(2). Grade: A/A grade , B/B grade and Economical grade

(3). Origin of film: imported film (Dynea brand or Stora Enso brand) / China local film

(4). Core: poplar

(5). Grade of the core: AA grade, A+ grade, A grade, B+ grade, B grade, C+ grade (don’t supply C grade)

(6). Glue: MR glue, WBP(melamine), WBP(phenolic)

(7). Size: 1220X2440mm, 1250X2500mm,1500X3000mm or as per your requirement

(8). Thickness: 4mm-30mm

(9). Packing: Standard seaworthy packing.

2. The characteristics of poplar film faced plywood

(1). The appearance of A/A grade looks perfect. The appearance of good grade looks good .

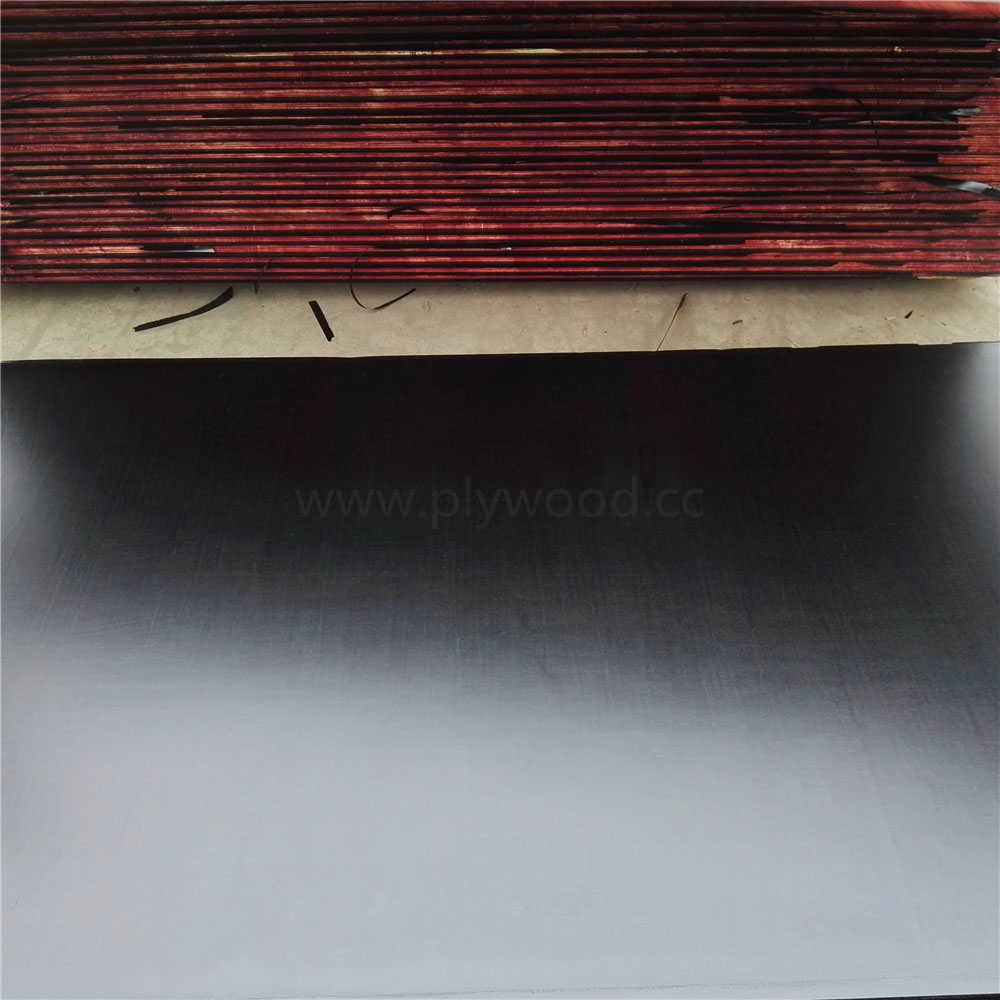

(2). The poplar film faced plywood is very flat and smooth .

(3). The grade of core varies from high grade (A+ or A grade) to Economical grade (finger jointed core) .

(4). The poplar core veneers can be whole piece core veneers(A+ grade, A grade) , medium size core veneers (B+ grade, B grade) and finger jointed core .

(5). The inner quality of poplar film faced plywood varies from best quality to economical quality .

(6). A/A grade Poplar film faced plywood is cheaper than A/A grade birch/hardwood film faced plywood. So we can say that poplar film faced plywood is good quality and economical .

3. The common construction/quality-requirement

Customers usually require the poplar film faced plywood as the following:

Economical grade:

Film faced plywood, GOOD grade, finger jointed core , brown film , one time press, WBP or MR glue

Good grade:

Film faced plywood, GOOD grade, fresh poplar core veneers, brown film , one time press, WBP melamine glue

Better grade:

Film faced plywood, A/A grade, fresh poplar core veneers, brown film , two time press, WBP melamine glue

High grade:

Film faced plywood, A/A grade, fresh poplar core veneers, brown film or imported film (Dynea brand or Stora Enso brand) , three time press, WBP(phenolic / good melamine) glue

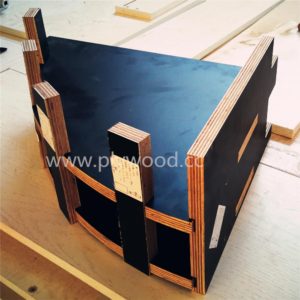

4.The application of poplar film faced plywood

Use as concrete shuttering form, building materials, for making high quality furniture and so on .

5. The staple market of poplar film faced plywood

About 60% of poplar film faced plywood are exported to Europe , about 40% are exported to Middle East and other countries .

Related Products:

Loading Quantity:

20'GP(contains 8pallets,22CBM)

40'HQ(contains 18pallets,50CBM)

Standard Seaworthy Packing method:

plywood is wrapped with a plastic bag and packed with packing plywood/MDF/carton (upon your request) ,loaded on Pallet .

Delivery Time: Within 15-25 days after got the deposit / sight L/C

Port of Loading: Qingdao port or Lianyungang port, China

Minimum Order Quantity: 1x20'GP container 8pallets/22cbm

Payment Terms:

1. 30%T/T as deposit, 70% T/T against B/L copy

2. 100% Irrevocable L/C at sight